Parts one and two of the Patagonia Fishing Boot tale described the quick initiation of the project and the research that we did to lay the groundwork for the design of the boots, which is always the funnest part of projects. The hard part comes next: what do to with our newfound knowledge? Can we actually create a product that fulfills the needs that we’ve identified, and if so, can the even more difficult task of marketing and distributing it into a traditional and fickle market be accomplished?

First we had to find a factory. By this time in the evolution of Patagonia footwear we had created and sold the CFS paddling shoe and some American-made sandals:

We realized that at least in the case of the CFS we needed to update the product and move away from the exposure to the Italian factory we had initially worked with for a variety of reasons. We had also engaged consultant Jim Granger, a venerable industry shoe dog with deep connections (who had recently started a cool new company called “Native Earth” footwear specializing in – as he called them – “ancient designs” for renaissance fairs; it’s worth a pic of one of them here since they are so cool:

Jim in turn introduced us to a Korean factory called Haksan. Korea was – according to Jim – the “Italy of Asia” in terms of footwear design and development, and Koreans were investing heavily in factories in northern China to take advantage of the cheaper labor there. I reached out to Haksan, and coincidentally it turned out that Haksan’s owner was going to be in Los Angeles for a trip and could take an afternoon to swing up to Ventura to meet with us.

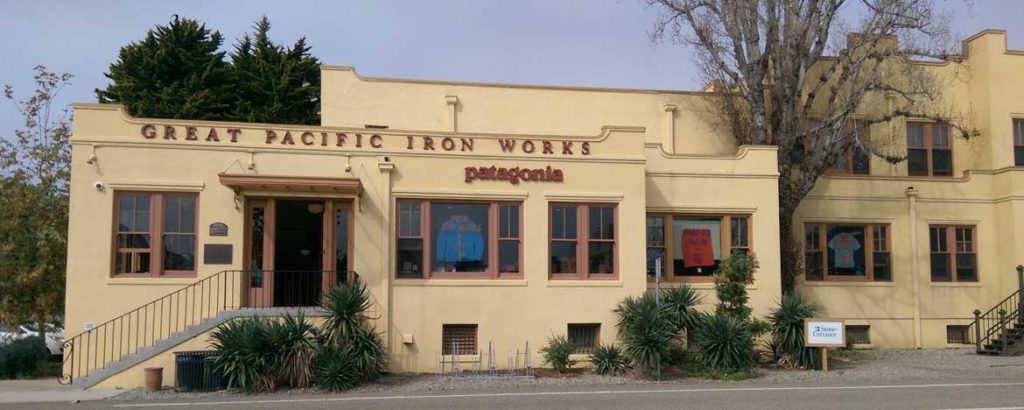

Mr Bill Lee rolled into the Patagonia parking lot and after pleasantries we embarked on a tour of Patagonia’s headquarters, which is always a fun trip for visitors.

Between the warm and inviting tiled building, front and center daycare, a bike rack out front stuffed with beach cruisers, a cute café, wide open office space filled with people wearing t-shirts, shorts, and flip flops I had no doubt that it would be quite different from what these Korean industrialists were accustomed to.

But Patagonia has a good presence in Korea and Mr Bill Lee was savvy enough to know how successful the company was that he knew this was the real deal.

By now designer Bruce Rogers and I had finished the drawings of the new paddling shoe and both styles of fishing boots, and we settled into a small conference room to go over the designs. We talked materials, lasts, fit, soles, techniques, etc. This went on for a while, and then came the question I had been dreading: “So Mr Tom, these are very nice designs. How many pairs do you anticipate doing?” Minimum Order Quantity – or MOQ – is a big deal for shoe factories, because between the lasts:

The molds required for the midsoles and outsoles:

the pattern cutting dies:

All of these need to be created for each size. It’s a big commitment.

It’s a healthy investment, and typically factories absorb all of those upfront costs – including the product development time that their employees spend – and then make all that money back with the production order. So having lots of pairs to amortize all those costs over is important, and at that time 20,000 pairs was a pretty typical MOQ, with maybe 10,000 pairs being acceptable (that number has since come down quite a bit, with greater efficiencies, big brands doing esoteric products, and the success of more brands starting small and going big).

I was prepared for Mr Bill Lee’s question, and launched into a discussion about how great of a brand Patagonia was, how fishing and kayaking were important and growing markets for the brand, how Patagonia was unique for its ability to maintain styles for multiple seasons – and even years, being a Patagonia factory was a great kudo for a factory to advertise to other clients, and how deeply symbiotic the relationships were between Patagonia and its factories (all very much true). Mr Bill Lee patiently sat through all this and finally said something to the effect of “yes, that’s all well and fine, but how many will you order?”

I took a deep breath and said “Well, with the freshwater boot we are likely doing about 2000 pairs, probably a few more for the paddling shoe, and while we see good potential for the Marlwalker, it is a new market and that would probably be more in the 1000 pair range.” All of which was actually a bit overly optimistic.

There was an awkward silence. Mr Bill Lee looked over at his vice president, who looked back at him. They both looked at me. I sorta shrugged. Mr Bill Lee was the first to speak. “Is this some sort of joke? Do you really think that any factory would take on this project?” I again started in on my exhortation of the potential when he held up his hand to stop me. “I am deeply offended that you have asked me to come here and waste my valuable time from my US business trip. We are a serious shoe factory. You are clearly not serious about this project. This meeting is over.” He looked over at his VP, stood up, grabbed his coat, they walked out of the room, and without another look they strode out to the rental car, the doors slammed, and they sped out of the parking lot.

Well, that meeting didn’t go as well as I would have liked. Part of the reason that we had endured the pains of working with an Italian factory and a US manufacturer for the original styles was that we knew that MOQ’s would not be as much of an issue with those factories who were accustomed to smaller orders, and we would be willing to pay a bit more for the lower amortization rate. The meeting with Mr Bill Lee seemed to reinforce the possibility that “real” footwear manufacturing was simply not possible at the scale that we needed at that time.

For a day or two I was in a bit of a funk; we knew that we had a great opportunity, but actually getting them made was perhaps too high of a hurdle to jump over. And then about three days hence it happened: my email inbox popped up with a message from Mr Bill Lee. It read something to the effect of “Dear Mr. Tom. We have reconsidered our position, and Haksan will be happy to partner with you and Patagonia to develop and produce the new footwear. Please send the product details asap so that I can have our team start working on it. Best Regards, Bill.” And that was that: we had a source.

I never ended up asking Bill what made him reconsider, nor did he venture it, but it was the beginning of a long relationship, to the point where we met up a couple of times a year and he always used the opportunity to call me part of his “American Family,” And indeed Haksan not only made Patagonia fishing boots for years but was also the source for the boots I did for the US Marine Corps years later.

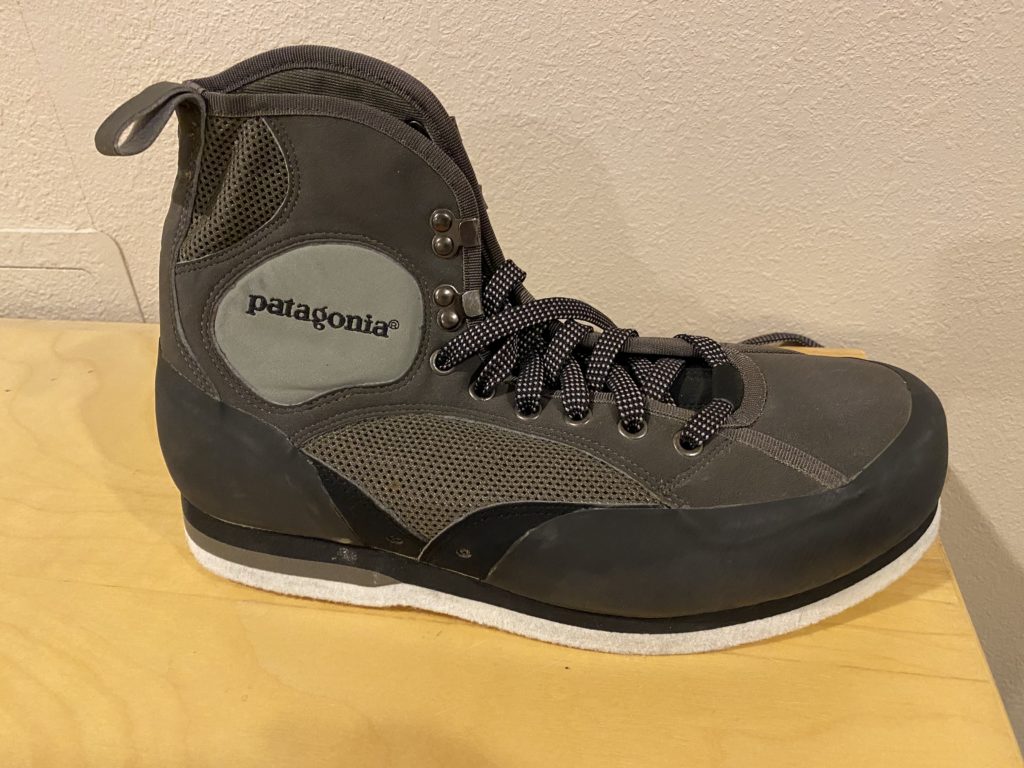

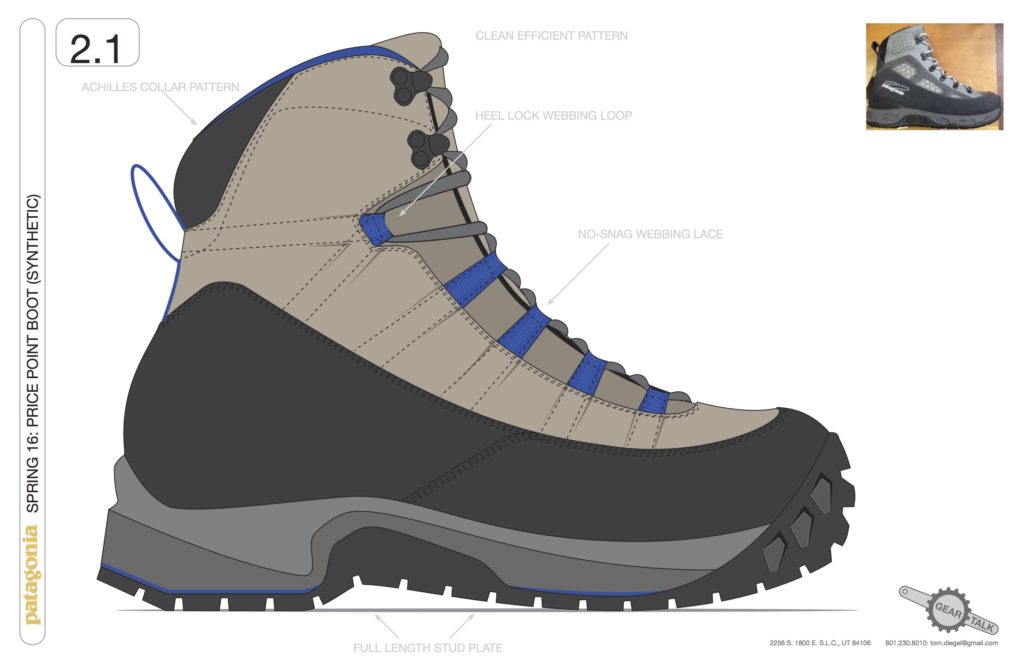

In any case, we were off, and started working furiously on getting samples made. Indeed, we had the opportunity to keep some costs down: the freshwater boot was to have felt soles so we didn’t have to do outsole molds, and for the Marlwalker we looked through their vault of old basketball sole designs that we could appropriate and include the Patagonia logo (a little known secret). Bruce’s upper designs were detailed enough that Haksan only had to do one or two rounds of prototypes before we were done:

We used pretty light, muted colors for some camouflage in the flats, and light colored soles to not mark up the white panga boats. Big drainage so that you could walk without sloshing, with tight enough mesh that debris didn’t float in.

The development of the shoes went so quickly and smoothly that we had plenty of time to work on the other crucial aspects of the boots’ introduction: the boxes, the catalog presentation, the distribution to the dealers, the various point-of-purchase displays, the fishing magazine ads, etc.

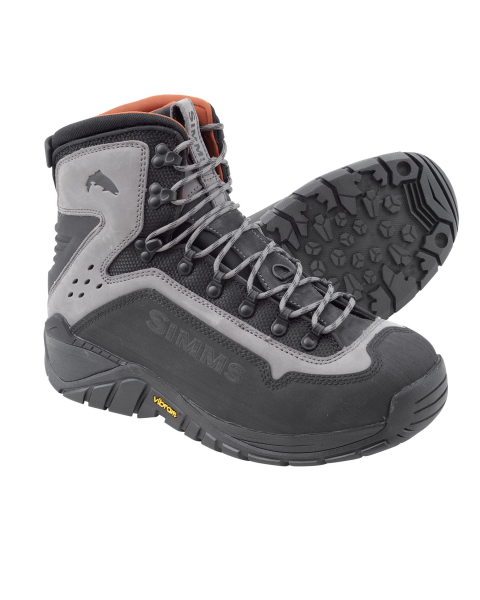

And it all worked. At the next Fly Fishing trade show in Denver we introduced the boots and it was pretty rewarding to hang out in the booth and see how excited the dealers were, and the orders came in bigger than we expected. At the show I saw my old friend – and future business partner – shoe designer Chuck Roth looking over the new Patagonia boots carefully with KC Walsh, the owner of Simms Fishing, and relished “busting” them for it (good naturedly, of course!). The production went smoothly and the boots were all delivered on time and we had few quality issues, both of which were definitely NOT the case with the Italian and American-made products we had started out doing.

Here is a pair from my old pal Paul Ecker, who is still rocking the originals:

Paul fulfilled a lifelong dream to go flats fishing at Christmas Island some years later:

and took a pair of the updated Marlwalkers:

At one point we realized that the Patagonia store in NYC’s Soho district kept demanding more and more of the Marlwalkers, and apparently for a while it was the hot dance footwear at clubs!

Haksan ultimately built a new factory in Vietnam and Mr. Bill Lee told me that they were applying lots of expensive aspects to it to accommodate Patagonia’s high environmental standards, which was ironic because despite years of fishing boot production where they were repeatedly warned by Patagonia to up their environmental standards the new factory did not actually fulfill the standards and ultimately Patagonia changed factories a couple of times. Now Danner is actually making Patagonia’s boots in their Portland, Oregon facility. Alas, Mr Bill Lee passed away too soon a couple of years ago, and his son is now leading Haksan.

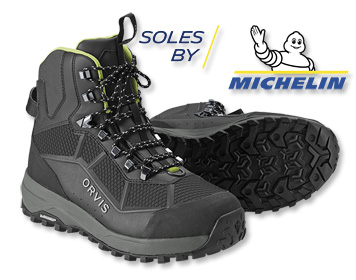

And now, 20 years hence, most fishing boots are still descendants of the original Patagonia boots,

In the first few years there were brands – big and small – that were reproducing the Patagonia shoes almost stitch for stitch.

Coincidentally, Chuck Roth (of previous Simms fame) and I actually worked on updating Patagonia’s boots in 2014!

Now flats fishing footwear is indeed an actual market.

And Simms even decided to do a neoprene flats bootie:

Felt soles were found to be carriers/distributors of the of the awful Whirling Disease and other waterborne diseases, so sticky rubber has become more common, and I believe that Yvon Chouinard sort of pioneered the use of soft aluminum crampons for fishing boots to grab underwater rocks, and aluminum cleats screwed into outsole lugs is quite common now.

From that fateful day when Yvon shuffled on over and said “I wanna do some fishing boots. Everything out there is shit!” it was a fun and fulfilling process to understand the demands of the activity and work hard at making good products for dedicated fishermen. Thanks again to YC for the inspiration and to Patagonia for their commitment and support throughout the journey. And thanks to Park City’s uber-energy guy Canice Hart, who was a Patagonia sales rep and amazingly has kept pairs of the original boots in their pristine condition and supplied the pics!

Loved this story….really reminded me of reading Shoe Dog, but the complete reversal of Mr. Bill really has me baffled. Someone got to him helping him understand about getting into the market early and how that would be worthwhile probably. At least, that’s my guess.

Great read but part 2 was really vintage Diegel with you turning the exploration trip into a fishing and biking junket as well.

Now I know the “rest of the story” and how Simms stole your concept!

Thanks Dave. I was really quite surprised by Bill’s reversal, and after later learning a bit more about Korean business culture with its paternalistic, hierarchical, and kind of honor-based system I realized it probably took a lot of pride-swallowing to change his mind than I even originally thought.

I would not say so much that Simms “stole the concept”; like every industry the outdoor/hook-n-bullet competitors keep a close eye on each other and expand on and improve on concepts. Yvon himself had (has?) a great quote along these lines: “there are no more great ideas; just new combinations of old ideas.” (he may have even poached that line!). I think that I would not be nearly as pleased with the outcome of the project had the market NOT gone that direction; the virtual Trash Heap of the footwear industry no doubt has plenty of shoes that are either at least reflective of or are actual manifestations of a handful of my ill-begotten ideas!

Fun read Tomster. But how many pairs did Patagonia end up producing overall (or per year)? Did it end up being profitable for Haksan?

Ah Rocky, keeping me honest! I honestly don’t remember specifically what the numbers were, but they all did a bit better than expected, and we did keep the styles around mostly unchanged for quite some time, so the cycle of seasonal style changes was kept down. I don’t actually know if it was that profitable for Haksan per se, but as one private company working with another (ie not accountable to shareholders) I think all the principals (ie owners) were happy with what they got out of the projects and relationship.

Hey Tom, Thanks for the excellent trip down memory lane. Fun to revisit some of the past experiences and fill in a few of the blanks. I appreciate you introducing Mr. Bill Lee to me and the ongoing relationship I have had with Bill and now his son Mathew. Our relationship started in much the same manner, with Bill being skeptical about building dog boots for us and then embracing our project because it challenged his team to think differently. A few years into our project, Bill proudly showed me an article written about Haksan abilities and Bill’s leadership skills that was in a well respected Korean newspaper. The article celebrated Bill’s ability to take calculated risks and explore new business opportunities, specifically building dog boots on proprietary lasts that we co-developed. I have so many fond memories of Mr. Bill Lee, he truly adopted many of us as his american family and it was heartfelt. I miss Bill, he was a great guy. Thanks so much for the introduction to Bill and Haksan.

Hey Tom! Great article. Not sure if you remember me but I was part of the downtown Bike Gallery crew back in the early 90’s….

First thing that popped into my head was “Diegel isn’t a fisherman is he?! “ I spent hundreds of days fly fishing the Deschutes when I was living in Portland. I worked at Countrysports in downtown and I think we carried the Patagonia boots at the store.

I’m glad to know that you brought these boots to market! Now I’ll have another good story to tell my fellow Patagonia wearing fishing buddies.

Good to see you after all these years!

Dan

right on Dan. Blast from the past indeed. Great to hear from you. Glad to hear you put them boots to some good use!